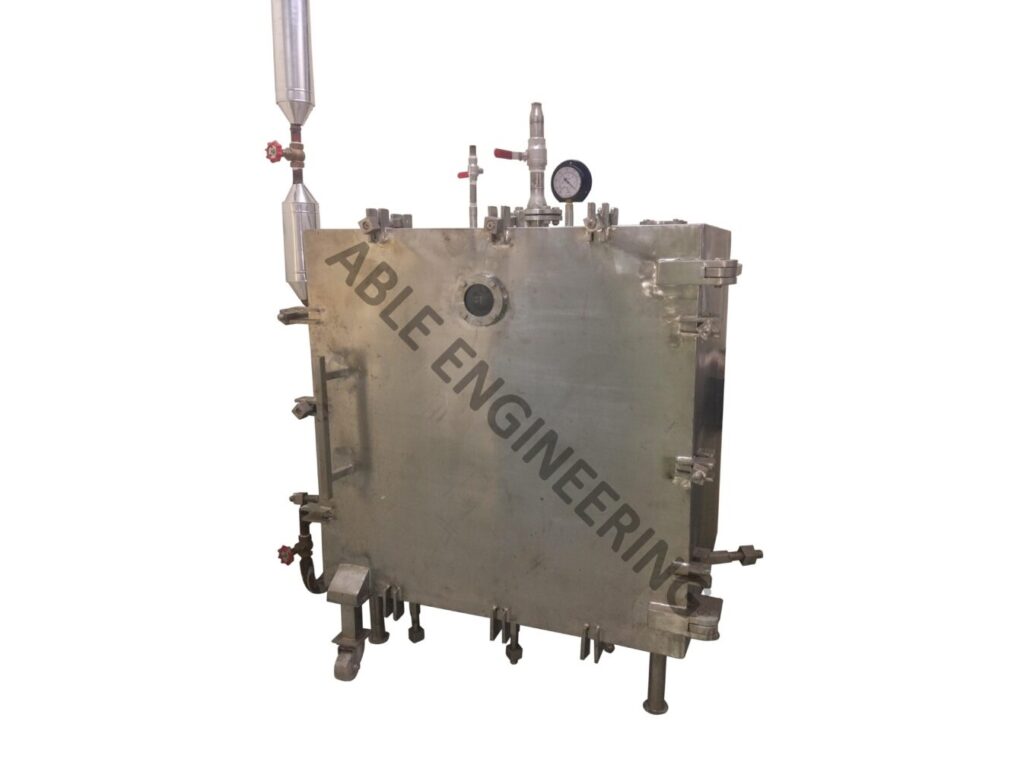

The Vacuum Tray Dryer (VTD) is suitable for drying thermally sensitive materials that are easily resolved, polymerized, or deteriorated at higher temperatures. It is widely used in herbal extraction plants and pharmaceutical plants. Sterilization can be conducted before the drying process, during which no matter is allowed to enter the product. Able Engineering manufactures the most qualitative vacuum tray dryer, which is well known for its high quality and efficiency levels. This gamut of products is in high demand in the market for the heating and drying up of various items involved in the manufacturing processes of several industries.

Inside the vacuum dryer, materials to be dried are kept on the trays, and pressure is reduced through the vacuum pump. The dryer door is tightly shut, and between trays and jackets, steam passes through space so that heat transfer occurs by conduction.

Features of Vacuum Tray Dryer (VTD):-

- Light and sight glasses are provided for checking the processing of the material.

- A temperature gauge and vacuum gauge are provided for monitoring.

- Modified lock hinge for better grip and easily sealed the chamber.

- A gasket is provided in the door to reduce the possibility of leakage.

- Lower drying temperatures

- Due to the large surface area, faster drying takes place.

- When compared to standard dryers, it dries a large amount of moisture.

- Consume less power than other traditional drying technologies.

Optional:-

- A digital temperature meter can be provided.

- High mirror polish can be provided.

- 12 to 96 Trays.

ABOUT US

Able Engineers Private Limited, also known as Able Engineering, is a leading manufacturer of herbal extraction plant machinery and a fabrication company that offers our clients a wide breadth of experience and knowledge. Our expert team has extensive knowledge of herbal extraction plants and machinery, pharmaceutical plant machinery, food processing plants and machinery, dairy and milk processing plants and machinery, chemical plant machinery, and calcium processing plants. We are able to satisfy the needs of a wide range of clients. Having been involved in projects covering a broad spread of industrial sectors, including reactors, rotary extractors, and other pharmaceutical machinery, we have the flexibility to tailor our production to meet the needs of our clients. Our experience and expertise also allow us to work closely with our clients from the design stages of projects until final dispatch. This combination of steel fabrication, rolling, forming, and welding, together with a working knowledge of the industries served, allows us to provide a full and comprehensive service with the aim of complete customer satisfaction.

Our every employee believes value engineering is an important part of our work, and we provide solutions, not just products. Our teams of qualified, experienced engineers and technicians can create and build to client specifications, whatever the challenge. Our clients are guaranteed the highest levels of product quality and workmanship, including on-time completion. Our mission is to provide high-quality service and products combined with trusted client partnerships, to maintain high health and safety levels, and to provide solutions to the client’s needs.

Our experience and expertise also allow us to work closely with our clients from the design stages until final dispatch. This combination of steel fabrication, rolling, forming, and welding, together with a working practical knowledge of the industries served, allows us to provide a full and comprehensive service with the aim of complete customer satisfaction.

Our Values

- Quality and safety first.

- Monitoring continuous improvement through learning and development.

- Innovation and creativity in solving problems.

- An empowered, committed and motivated workforce.