Product > filtration > Four Point Centrifuge

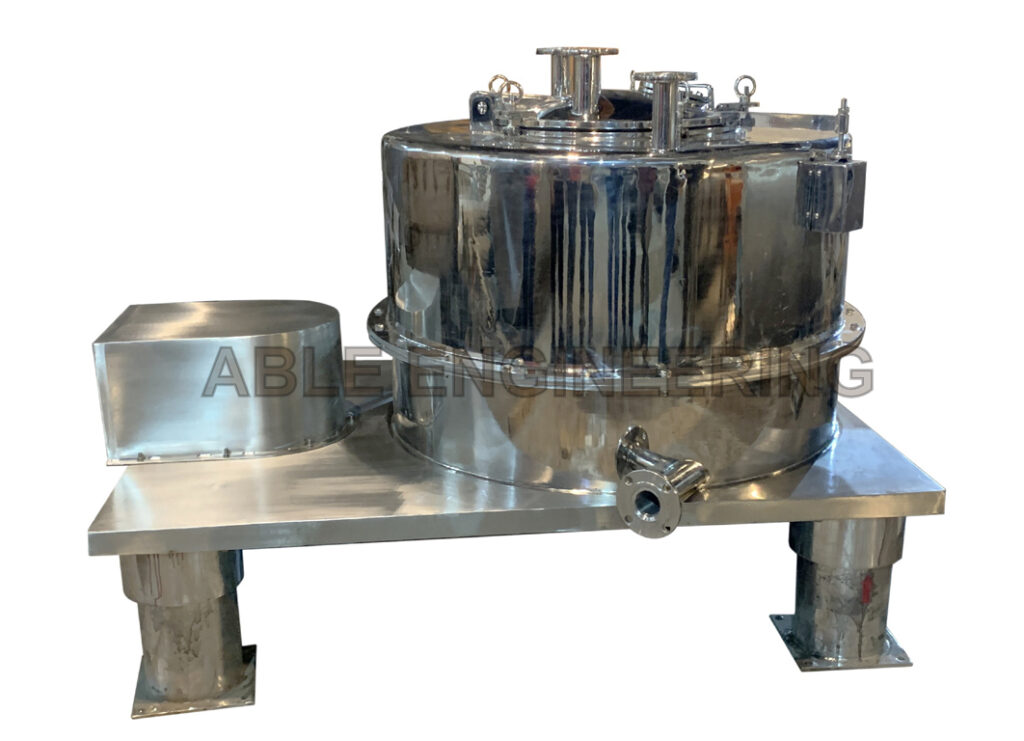

Four Point Centrifuge

Able Engineers Private Limited is a leading manufacturer of a Four-Point Centrifuge machine. A centrifuge is the most energy-efficient machine that separates a solid from a liquid. At high rotational speed, a four-point centrifuge separates components of different densities. A centrifuge is a unique energy-efficient machine that works by spinning a vessel containing the material to be separated at high speed. The centrifuge spins at high speeds and pushes the heavy particles, usually the solids, to the peripheral side of the vessel, in addition to swinging its contents around and using their inertia to make them separate. Able Engineers Private Limited is a manufacturer, supplier, and exporter of highly durable and energy-efficient centrifuge machines in India.

How it works:

In basket centrifuges, the solids and liquids are separated by centrifugal force using filter media (usually cloth) mounted over supporting mesh, which are supported together inside the rotating basket. The slurry to be filtered is fed through the feed nozzles to the basket, and due to centrifugal force, the liquid is forced out through the filter media while solids are retained within the filter media inside the basket. These solids are then separated or discharged by various methods, namely: manually, with a bag lifting basket, through a scrapper operated manually, pneumatically, or hydraulically, for which different models are available.

Features of Four-point Top Discharge Centrifuge:

- Bottom-driven, manual top discharge.

- Dynamically balanced SS 304 or 316 inner basket.

- Bearing housing from graded C.I. with SS lining.

- Manual band brake.

- Main shaft—EN 24, hardened, and ground.

- Fabricated outer body with an Interlock safety cover.

- Clutch pulley or fluid coupling to reduce the initial heavy load on the motor and provide gradual acceleration with the help of the necessary belt drive.

- It comes with a supporting system: an inertia plate of 50 mm MS lined by 2 mm SS 304 with a Visco damper.

Advantages of 4 Point Mounting:

- The level of vibration is much lower and it operates very smoothly.

- Can be mounted on the upper floor and easily relocated.

- Almost negligible maintenance cost.

- The working area is free from abstracts, and a clean area can be maintained.

MODEL

Basket diameter

Basket height

Filter surface Area

Useful volume

Max. load

Max. load @ Bulk Density 1.0

Motor power for main drive

24″ x 12 “

600

300

0.57

45

45

1200

3

32″ x 16 “

800

400

1

100

100

1100

7.5

36″ x 18″

900

400

1.32

150

150

1100

10

48″ x 20″

1210

490

1.86

280

300

900

15

Unit

MM

MM

MM

DM3

KG

RPM

HP

About Us

Able Engineers Private Limited, also known as Able Engineering, is a Fabrication company that offers our clients a wide breadth of experience and knowledge. Our team of professionals has vast experience in the Herbal Extraction Plants & Herbal and Solvent Extraction Plant Machinery, Pharmaceutical Plant Machinery, Food Processing Plant & Food Processing Plant Machinery, and Chemical Plant Machinery & Calcium Machinery plants. We are able to satisfy the needs of a wide range of clients. Having been involved in projects covering a broad range of industrial sectors, including reactors, rotary extractors, and other pharmaceutical machinery, we have the flexibility to tailor our production to meet the needs of our clients.

Our experience and expertise also allow us to work closely with our clients from the design stages until final dispatch. This combination of steel fabrication, rolling, forming, and welding, together with a working practical knowledge of the industries served, allows us to provide a full and comprehensive service with the aim of complete customer satisfaction.

Our every employee believes value engineering is an important part of our work, and we provide solutions, not just products. Our teams of qualified, experienced engineers and technicians can create and build to client specifications, whatever the challenge. The clients have ensured the highest levels of product quality and workmanship, including on-time completion. Our mission is to provide high-quality service/ product combined with trusted client partnership and to maintain high health and safety levels and solutions to the client’s needs.

Our Values

- Quality and safety first.

- Monitoring continuous improvement through learning and development.

- Innovation and creativity in solving problems.

- An empowered, committed, and motivated workforce.