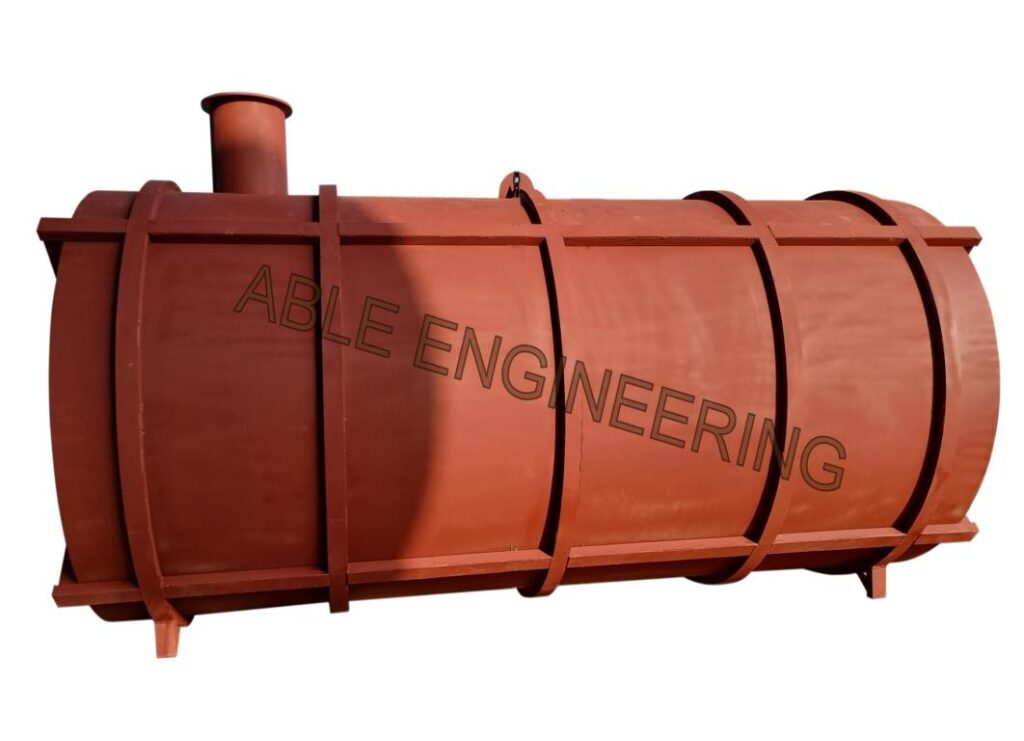

Product > Others > Storage Tank

Solvent Storage Tank

We design and manufacture Solvent Storage Tank to store solvent in the Herbal Extraction Plant. Storage Tanks are containers that hold liquids, compressed gases, or mediums used for the short- or long-term storage of heat or cold. Storage tanks are often cylindrical in shape, perpendicular to the ground, with flat bottoms, and a fixed, frangible, or floating roof. These tanks can be used to hold materials such as petroleum, waste matter, water, chemicals, and other hazardous materials. These tanks are available in many shapes: vertical and horizontal cylindrical; open top and closed top; flat bottom, cone bottom, slope bottom, and dish bottom. Most Storage Tanks for handling liquids during transportation are designed to handle varying degrees of pressure. These tanks have a wide demand in various processing industries because they are highly qualitative and cost-effective.

Able Engineers Private Limited manufactures Solvent Storage Tanks having a capacity in the range of 250 litres to 150,000 liters. We provide full customization on our Storage Tanks as per the specifications and requirements of the client.

Types of Solvent Storage Tank:-

- Horizontal Storage Tanks.

- Vertical Storage Tanks.

- Elliptical Shaped Storage Tanks.

- Dished Shaped Storage Tanks.

- Flat Storage Tanks.

- Conical Head Storage Tanks.

- Single, double, or triple wall tank.

- Triple wall tank with limpet, dimple, helical, or plain jacket.

- High-speed or low-speed agitators.

- Material of construction SS 304 /316/304L/316L.

- Suitable for indoor or outdoor installation.

About Us

Able Engineers Private Limited, also known as Able Engineering, is a Fabrication company that offers our clients a wide breadth of experience and knowledge. Our team of professionals has vast experience in the Herbal Extraction Plants & Herbal and Solvent Extraction Plant Machinery, Pharmaceutical Plant Machinery, Food Processing Plant & Food Processing Plant Machinery, and Chemical Plant Machinery & Calcium Machinery plants. We are able to satisfy the needs of a wide range of clients. Having been involved in projects covering a broad range of industrial sectors, including reactors, rotary extractors, and other pharmaceutical machinery, we have the flexibility to tailor our production to meet the needs of our clients.

Our experience and expertise also allow us to work closely with our clients from the design stages until final dispatch. This combination of steel fabrication, rolling, forming, and welding, together with a working practical knowledge of the industries served, allows us to provide a full and comprehensive service with the aim of complete customer satisfaction.

Our every employee believes value engineering is an important part of our work, and we provide solutions, not just products. Our teams of qualified, experienced engineers and technicians can create and build to client specifications, whatever the challenge. The clients have ensured the highest levels of product quality and workmanship, including on-time completion. Our mission is to provide high-quality service/ product combined with trusted client partnership and to maintain high health and safety levels and solutions to the client’s needs.

Our Values

- Quality and safety first.

- Monitoring continuous improvement through learning and development.

- Innovation and creativity in solving problems.

- An empowered, committed, and motivated workforce.